Machinery

CNC vertical lathes with driven tools

On our precise carousel lathes with driven tools we can machine your parts up to an outside diameter of 6.000 mm. Following operations are available:

- Turning

- Milling

- Drilling

- Gearcutting

- Grinding

In the field of CNC control we relied on the proven Sinumerik 840Dsl

CNC drilling center for gearcutting and drilling operations

A specially converted drilling center allows even special operations and drilling outside the center as they are needed in particular in belt-driven slweing bearings, for example used in large wind turbines. Unconventional teeth therefore are possible. We are able to offer special solutions for specific customer solutions.

Again, we rely on the Sinumerik 840 DSlL

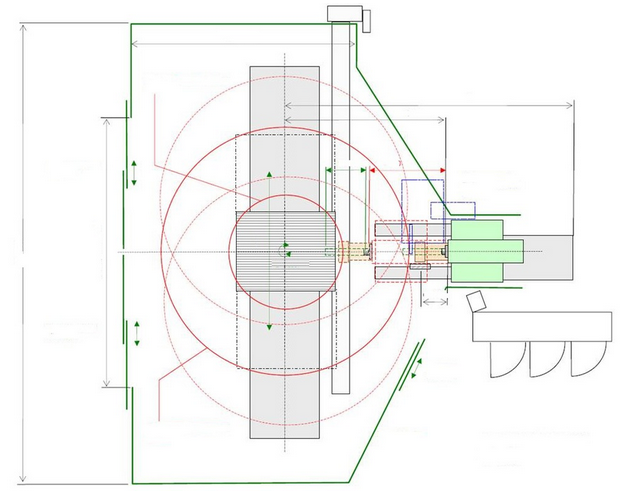

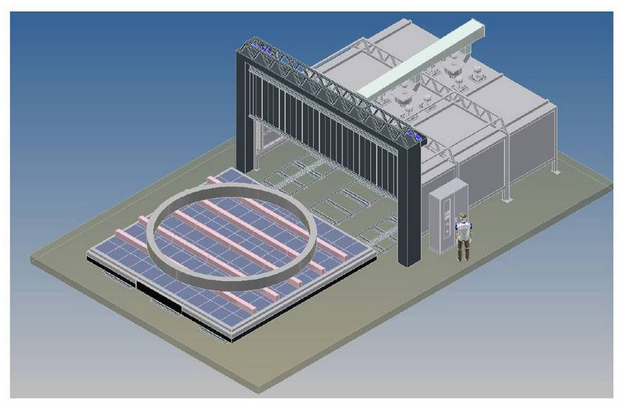

Fully automatic CNC-controlled inductive surface hardening machine

One of the most modern machines in the world, especially in its diameter, we have available for inductive surface hardening. Parts from 900 mm up to 6000 mm can get its wearout protection hardening for raceways and gears here. Hardening depths up to 10 mm can be achieved reliably thanks to modern IGBT-based induction generators.

With two 200kW generators we divide the process into two parts, and so prevent overheating of the surface and guarantee a stable and durable hardness which is also up to the toughest environments.

Again, we rely on the CNC Sinumerik 840 DSL from Siemens.

CNC-controlled tempering furnace with component sensors

After the inductive surface hardening process, we let our components in a special oven to prevent cracking of the hardened surfaces and to take frictions away from the parts. Our oven has a working area of 6,000 mm x 6,000 mm x 1,000 mm.

Special to the furnace control connected heat sensors monitor directly on the part the CNC-controlled heating and cooling process. Maximum controlling and stable processes for heavy-duty components.